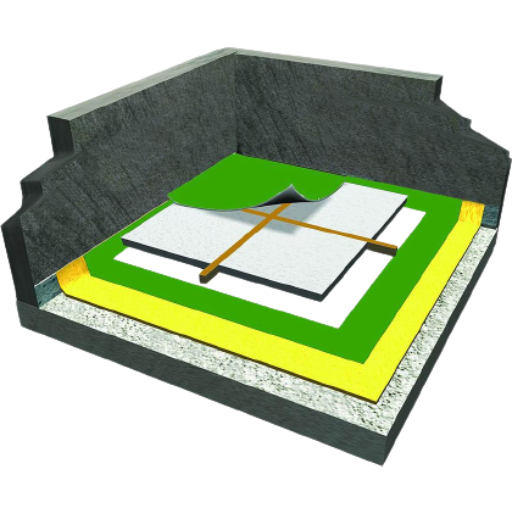

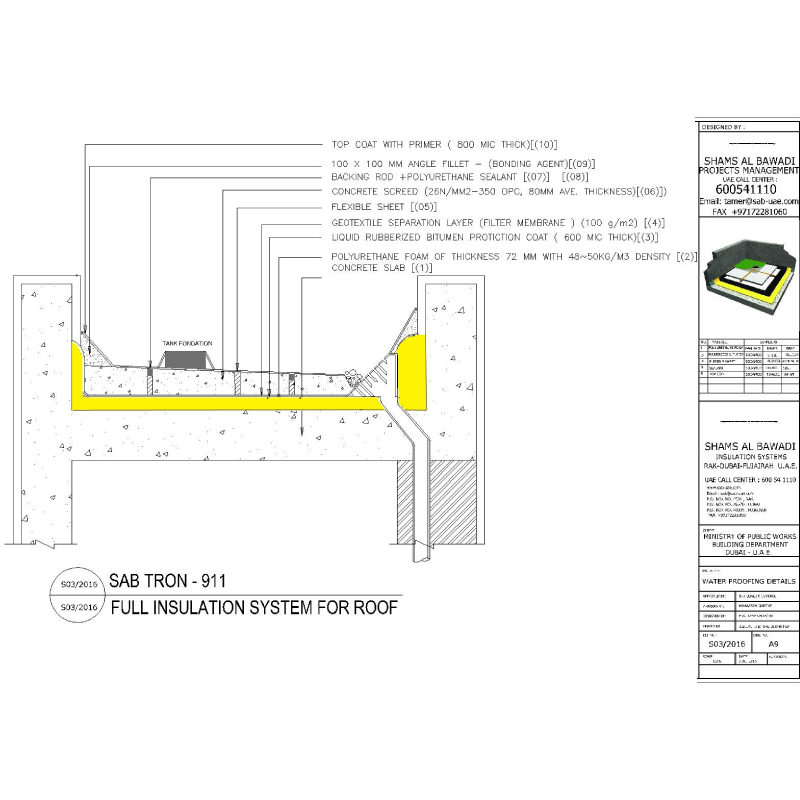

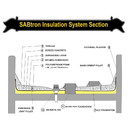

SAB® Tron – Combo system, (Integrated Waterproofing System) / Roof.

1. Clean the roof slab from all dust or debris by using compressed air, directly before Polyurethane implementation.

2. Applying polyurethane foaming spray, (averagely: 60-65 mm thick & 45-50 Kg/m³ densities roof )

3. water testing should be by using sweet water ,for 24-48 hours, this water test will give high opportunity to discover any leakage might be happen, either it was due to manufacturing defect or poor quality materials, this step can be after polyurethane or after rubberized application ( this procedure should be on the main contractor responsibility, and under consultant engineer supervision)

4. Applying one coating (Acrylic) top coating, spray Applied, which is Acrylic based, and Non-flammable. (Application should be by spray ).

5. covering all the above mentioned steps by using one layer of non woven polyester synthetic fabric filter membrane (Geotextile Separation Layer 100 g/m² )

6. Dividing the roof slab into multiple squares (its area is 300cm * 300cm), then execute ridges by using the flexible sheets with thickness 12mm, and its height is matching with roof slope 1/100 (that will increase 1 cm height for each 1m length), taking into consideration the water pipe will forming the starting point to execute ridges in this stage, and its screed should be at 4cm minimally.

7. Casting screed of Ready Mix Concrete–OPC- 20N/m³ – without ice.

8. Soften the casting ready mix concrete by using the helicopter, this procedure should be on the same casting day and when the screed starts to be dry.

9. Execute slope corners 20cm*20cm to cover the upper side of insulation layers along with the parapet, in order to avoid a high probability leaking in this weakness area.

10. Approximately 5 days later, be sure the casting screed ready mix concrete is well dry, than all flexible sheets must be removed very carefully, without causing any vandalism or damages in screed edges along with those flexible sheets that had been removed.

11. Filling the expansion joints by sponge 20mm thickness, then apply mastic coat minimally: 20mm height and 10mm width, to protect screed edges this forming important stage to avoid a high probability leaking in this weakness area.

12. Air conditions bases (main contractor responsibility) should implement on the top of the roof slab far away from expansion joints, this step should be before acrylic execution. Taking into consideration keeping the insulation system clean and safe.

apply (Acrylic) top coating, spray Applied, which transform from liquid texture during application into elastic and flexible coating when drying , and its specification : highly flexibility, Weather resistant, and High adhesion power